Chemists find better way to pack natural gas into fuel tanks

New flexible material could improve driving range of natural gas-powered vehicles

October 26, 2015

A new and innovative way to store methane could speed the development of natural gas-powered cars that don’t require the high pressures or cold temperatures of today’s compressed or liquefied natural gas vehicles.

Flexible MOFs undergo a dramatic structural change when they adsorb methane, rapidly going from a nonporous to a highly porous material. This animated gif shows one pore of the material. Jarad Mason graphic.

Natural gas is cleaner-burning than gasoline, and today there are more than 150,000 compressed natural gas (CNG) vehicles on the road in the United States, most of them trucks and buses. But until manufacturers can find a way to pack more methane into a tank at lower pressures and temperatures, allowing for a greater driving range and less hassle at the pump, passenger cars are unlikely to adopt natural gas as a fuel.

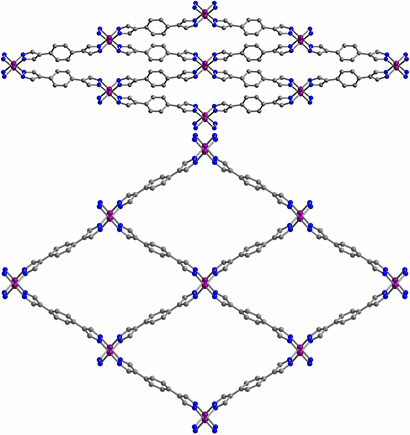

UC Berkeley chemists have now developed a porous and flexible material — a so-called metal-organic framework (MOF) — for storing methane that addresses these problems. The flexible MOF collapses when the methane is extracted to run the engine, but expands when the methane is pumped in at only moderate pressure, within the range produced by a home compressor.

“You could potentially fill up at home,” said Jeffrey Long, a UC Berkeley professor of chemistry who led the project.

The flexible MOF can be loaded with methane, the main ingredient of natural gas, at 35 to 65 times atmospheric pressure (500-900 psi), whereas compressed natural gas (CNG) vehicles compress natural gas into an empty tank under 250 atmospheres (3,600 psi).

Liquefied natural gas (LNG) vehicles operate at lower pressures but require significant insulation in the tank system to maintain the natural gas at minus-162 degrees Celsius (minus-260 degrees Fahrenheit) so that it remains liquid.

Next-gen NG vehicles

Long said that next-generation natural gas vehicles will require a material that binds the methane and packs it more densely into the fuel tank, providing a larger driving range. One of the major problems has been finding a material that absorbs the methane at a relatively low pressure, such as 35 atmospheres, but gives it all up at a pressure where the engine can operate, between 5 and 6 atmospheres. MOFs, which have a lot of internal surface area to adsorb gases — that is, for gas molecules to stick to the internal surfaces of the pores — and store them at high density, are one of the most promising materials for adsorbed natural gas (ANG) storage.

A cross-section through a flexible MOF shows how the chemical structure shifts when methane is absorbed. (Jarad Mason graphic)

“This is a big advance both in terms of capacity and thermal management,” Long said. “With these new flexible MOFs, you can get to capacities beyond what was thought possible with rigid MOFs.”

Among the other advantages of flexible MOFs, Long says, is that they do not heat up as much as other methane absorbers, so there is less cooling of the fuel required.

“If you fill a tank that has adsorbent, such as activated charcoal, when the methane binds it releases heat,” he said. “With our material, some of that heat goes into changing the structure of the material, so you have less heat to dissipate, less heat to manage. You don’t have to have as much cooling technology associated with filling your tank.”

The flexible MOF material could perhaps even be placed inside a balloon-like bag that stretches to accommodate the expanding MOF as methane is pumped in, so that some of the heat given off goes into stretching the bag.

Long and his colleagues at the National Institute of Standards and Technology and in Europe will publish their findings online Oct. 26 in advance of publication in the journal Nature.

Improving on-board natural-gas storage

Natural gas from oil wells is one of the cheapest and cleanest fossil fuels today, used widely to heat homes as well as in manufacturing and to produce electricity. It has yet to be widely adopted in the transportation sector, however, because of the expensive and large on-board compressed fuel tanks. In addition, gasoline packs over three times the energy density per volume as natural gas, even when compressed to 3,600 psi, which results in natural gas vehicles with a shorter driving range per fill-up.

In order to advance on-board natural gas storage, Ford Motor Company teamed up with UC Berkeley on this project, with funding from the Advanced Research Projects Agency–Energy (ARPA-E) of the U.S. Department of Energy. Ford is a leader in CNG/propane-prepped vehicles with more than 57,000 sold in the U.S. since 2009, more than all other major U.S. automakers combined.

According to Mike Veenstra, of Ford’s research and advanced engineering group in Dearborn, Michigan, Ford recognized that ANG has the potential to lower the cost of on-board tanks, station compressors and fuel along with serving to increase natural gas-powered vehicle driving range within the limited cargo space.

“Natural gas storage in porous materials provides the key advantage of being able to store significant amounts of natural gas at low pressures than compressed gas at the same conditions,” said Veenstra, the principal investigator of this ARPA-E project. “The advantage of low pressure is the benefit it provides both on-board the vehicle and off-board at the station. In addition, the low-pressure application facilitates novel concepts such as tanks with reduced wall thicknesses along with conformable concepts which aid in decreasing the need to achieve the equivalent volumetric capacity of compressed CNG at high pressure.”

Long has been exploring MOFs as gas adsorbers for a decade, hoping to use them to capture carbon dioxide emitted from power plants or store hydrogen in hydrogen-fueled vehicles, or to catalyze gas reactions for industry. Last year, however, a study by UC Berkeley’s Berend Smit found that rigid MOFs have a limited capacity to store methane. Long and graduate student and first author Jarad Mason instead turned to flexible MOFs, noting that they behave better when methane is pumped in and out.

The flexible MOFs they tested are based on cobalt and iron atoms dispersed throughout the structure, with links of benzenedipyrazolate (bdp). Both cobalt (bdp) and iron (bdp) are highly porous when expanded, but shrink to essentially no pores when collapsed.

Their first experiments on these compounds already surpass the theoretical limits for rigid MOFs, Long said. This is a fundamental discovery that now needs a lot of engineering to find out how best to take advantage of these new adsorbent properties.”

He and his colleagues are also now developing flexible MOFs to store hydrogen.

UC Berkeley co-authors are Julia Oktawiec, Mercedes Taylor, Jonathan Bachman and Miguel Gonzalez. To perform structural and thermodynamic studies of the MOFs with and without methane, the team collaborated with Matthew Hudson and Craig Brown of NIST; Julien Rodriguez and Philip Llewellyn of Aix-Marseille University in France; Antonio Cervellino of the Paul Scherrer Institute in Villigen, Switzerland; and Antonietta Guagliardi and Norberto Masciocchi of the To.Sca.Lab in Como, Italy.

RELATED INFORMATION

- Methane storage in flexible metal–organic frameworks with intrinsic thermal management (Nature)

- Jeff Long’s group website

- New material captures carbon at half the energy cost (March 2015)

- New material cuts energy costs of separating gas for plastics and fuels (March 2012)

- Breakthrough in designing cheaper, more efficient catalysts for fuel cells (February 2012)