New process vaporizes plastic bags and bottles, yielding gases to make new, recycled plastics

The catalytic process, discovered by researchers at UC Berkeley, efficiently reduces polymers to chemical precursors, bringing a circular economy for plastics one step closer to reality

Robert Sanders, UC Berkeley

August 29, 2024

A new chemical process can essentially vaporize plastics that dominate the waste stream today and turn them into hydrocarbon building blocks for new plastics.

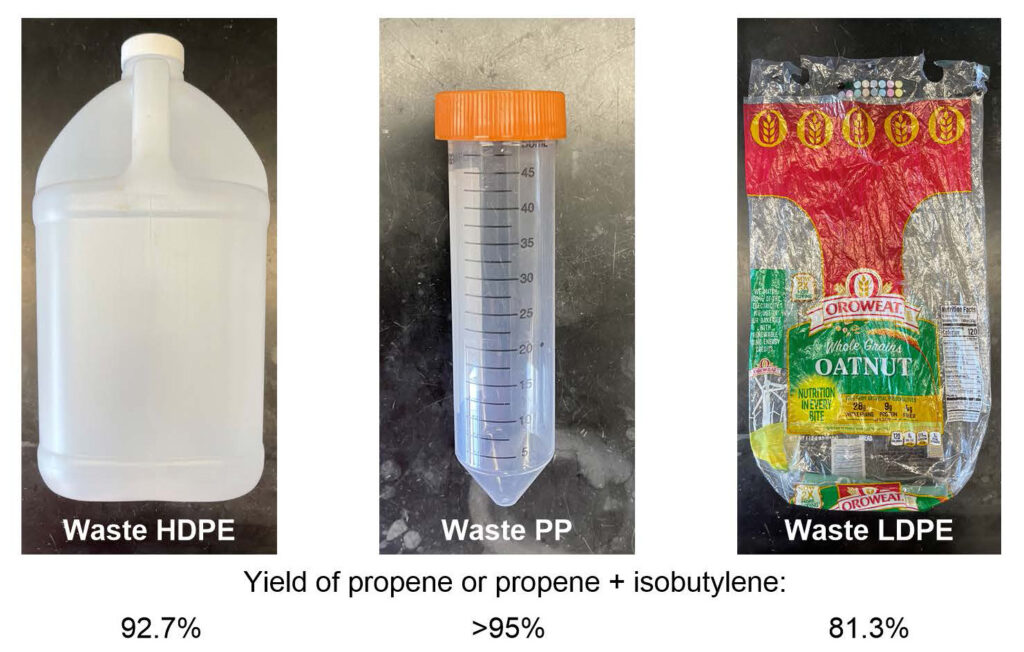

The catalytic process, developed at the University of California, Berkeley, works equally well with the two dominant types of post-consumer plastic waste: polyethylene, the component of most single-use plastic bags; and polypropylene, the stuff of hard plastics, from microwavable dishes to luggage. It also efficiently degrades a mix of these types of plastics.

The process, if scaled up, could help bring about a circular economy for many throwaway plastics, with the plastic waste converted back into the monomers used to make polymers, thereby reducing the fossil fuels used to make new plastics. Clear plastic water bottles made of polyethylene tetraphthalate (PET), a polyester, were designed in the 1980s to be recycled this way. But the volume of polyester plastics is minuscule compared to that of polyethylene and polypropylene plastics, referred to as polyolefins.

“We have an enormous amount of polyethylene and polypropylene in everyday objects, from lunch bags to laundry soap bottles to milk jugs — so much of what’s around us is made of these polyolefins,” said John Hartwig, a UC Berkeley professor of chemistry who led the research. “What we can now do, in principle, is take those objects and bring them back to the starting monomer by chemical reactions we’ve devised that cleave the typically stable carbon-carbon bonds. By doing so, we’ve come closer than anyone to give the same kind of circularity to polyethylene and polypropylene that you have for polyesters in water bottles.”

Hartwig, graduate student Richard J. “RJ” Conk, chemical engineer Alexis Bell, who is a UC Berkeley Professor of the Graduate School, and their colleagues will publish the details of the catalytic process on Aug. 29 in the journal Science.

A circular economy for plastics

Polyethylene and polypropylene plastics constitute about two-thirds of post-consumer plastic waste worldwide. About 80% ends up in landfills, is incinerated or simply tossed into the streets, often ending up as microplastics in streams and the ocean. The rest is recycled as low-value plastic, becoming decking materials, flowerpots and sporks.

To reduce this waste, researchers have been looking for ways to turn the plastics into something more valuable, such as the monomers that are polymerized to produce new plastics. This would create a circular polymer economy for plastics, reducing the need to make new plastics from petroleum, which generates greenhouse gases.

Two years ago, Hartwig and his UC Berkeley team came up with a process for breaking down polyethylene plastic bags into the monomer propylene — also called propene — that could then be reused to make polypropylene plastics. This chemical process employed three different bespoke heavy metal catalysts: one to add a carbon-carbon double bond to the polyethylene polymer and the other two to break the chain at this double bond and repeatedly snip off a carbon atom and, with ethylene, make propylene (C3H6) molecules until the polymer disappeared. But the catalysts were dissolved in the liquid reaction and short-lived, making it hard to recover them in an active form.

Robert Sanders, UC Berkeley

In the new process, the expensive, soluble metal catalysts have been replaced by cheaper solid ones commonly used in the chemical industry for continuous flow processes that reuse the catalyst. Continuous flow processes can be scaled up to handle large volumes of material.

Conk first experimented with these catalysts after consulting with Bell, an expert on heterogeneous catalysts, in the Department of Chemical and Biomolecular Engineering.

Synthesizing a catalyst of sodium on alumina, Conk found that it efficiently broke or cracked various kinds of polyolefin polymer chains, leaving one of the two pieces with a reactive carbon-carbon double bond at the end. A second catalyst, tungsten oxide on silica, added the carbon atom at the end of the chain to ethylene gas, which is constantly streamed through the reaction chamber, to form a propylene molecule. The latter process, called olefin metathesis, leaves behind a double bond that the catalyst can access again and again until the entire chain has been converted to propylene.

The same reaction occurs with polypropylene to form a combination of propene and a hydrocarbon called isobutylene. Isobutylene is used in the chemical industry to make polymers for products ranging from footballs to cosmetics and to make high-octane gasoline additives.

Surprisingly, the tungsten catalyst was even more effective than the sodium catalyst in breaking polypropylene chains.

“You can’t get much cheaper than sodium,” Hartwig said. “And tungsten is an earth-abundant metal used in the chemical industry in large scale, as opposed to our ruthenium metal catalysts that were more sensitive and more expensive. This combination of tungsten oxide on silica and sodium on alumina is like taking two different types of dirt and having them together disassemble the whole polymer chain into even higher yields of propene from ethylene and a combination of propene and isobutylene from polypropylene than we did with those more complex, expensive catalysts.”

Like a string of pearls

One key advantage of the new catalysts is that they avoid the need to remove hydrogen to form a breakable carbon-carbon double bond in the polymer, which was a feature of the researchers’ earlier process to deconstruct polyethylene. Such double bonds are an Achilles heel of a polymer, in the same way that the reactive carbon-oxygen bonds in polyester or PET make the plastic easier to recycle. Polyethylene and polypropylene don’t have this Achilles heel — their long chains of single carbon bonds are very strong.

John Hartwig and RJ Conk, UC Berkeley

“Think of the polyolefin polymer like a string of pearls,” Hartwig said. “The locks at the end prevent them from falling out. But if you clip the string in the middle, now you can remove one pearl at a time.”

The two catalysts together turned a nearly equal mixture of polyethylene and polypropylene into propylene and isobutylene — both gases at room temperature — with an efficiency of nearly 90%. For polyethylene or polypropylene alone, the yield was even higher.

Conk added plastic additives and different types of plastics to the reaction chamber to see how the catalytic reactions were affected by contaminants. Small amounts of these impurities barely affected the conversion efficiency, but small amounts of PET and polyvinyl chloride — PVC — significantly reduced the efficiency. This may not be a problem, however, because recycling methods already separate plastics by type.

Hartwig noted that while many researchers are hoping to redesign plastics from the ground up to be easily reused, today’s hard-to-recycle plastics will be a problem for decades.

“One can argue that we should do away with all polyethylene and polypropylene and use only new circular materials. But the world’s not going to do that for decades and decades. Polyolefins are cheap, and they have good properties, so everybody uses them,” Hartwig said. “People say if we could figure out a way to make them circular, it would be a big deal, and that’s what we’ve done. One can begin to imagine a commercial plant that would do this.”

Other co-authors of the paper are graduate students Jules Stahler, Jake Shi, Natalie Lefton and John Brunn of UC Berkeley and Ji Yang of Lawrence Berkeley National Laboratory. Shi, Hartwig and Bell are also affiliated with Berkeley Lab. The work was funded by the Department of Energy (DE-AC02-05CH11231).